Today’s most advanced medical devices are benefiting from the lightweight strength and manufacturing of flexible woven structures.

![]()

Weaving

Today’s most advanced medical devices are benefiting from the lightweight strength and manufacturing of flexible woven structures.

![]()

Custom Biomedical Textiles Weaving Solutions

We’ve partnered with the leaders in weaving equipment design and manufacture from around the globe, and worked to ensure that every optimal contact surface, yarn tensioning system, and pattern design technology is incorporated into our machinery. The result is a clear focus on creating the next generation of woven fabrics for our clients.

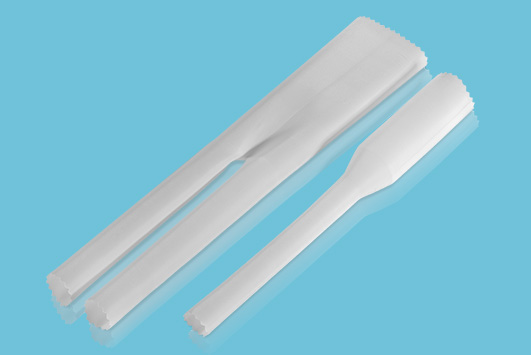

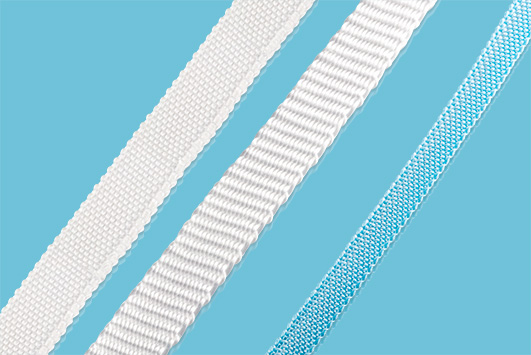

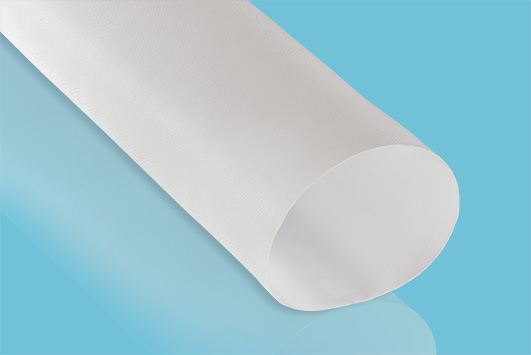

Narrow Weaving

- Narrow weaving machines with high density jacquard patterning

- Shuttle loom creating fabric with continuous edges

- Fully electronic weave cycle with positive warp drive let-off and fabric take-up systems

- Upgraded contact surfaces to improve biocompatibility

- Electronic design software networked to HMI including the use of 3D textile modeling software

- Every single yarn of the woven can be controlled individually which can make very unique structures – reference the 3D woven bifurcated graft

- Digital equipment allows for quick prototype iterations

- Tubular, bifurcated, bifurcated tubes, keyholes, windows, multi-layer, etc.

- Continuous take up (ideal for long lengths)

- Compatible with a wide variety of yarn types and sizes

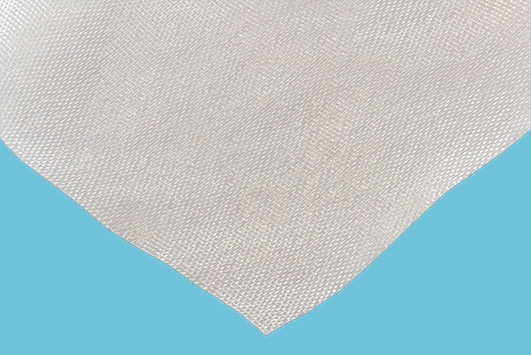

Broad Weaving

- Electronic dobby loom

- Ideal for flat or multi-layer woven fabric that requires laser cutting or post processing

- Maximum width of 20 inches

- Digital equipment allows for quick prototype iterations

- Compatible with a wide variety of yarn types and sizes

Narrow Weaving

- Narrow weaving machines with high density jacquard patterning

- Shuttle loom creating fabric with continuous edges

- Fully electronic weave cycle with positive warp drive let-off and fabric take-up systems

- Upgraded contact surfaces to improve biocompatibility

- Electronic design software networked to HMI including the use of 3D textile modeling software

- Every single yarn of the woven can be controlled individually which can make very unique structures – reference the 3D woven bifurcated graft

- Digital equipment allows for quick prototype iterations

- Tubular, bifurcated, bifurcated tubes, keyholes, windows, multi-layer, etc.

- Continuous take up (ideal for long lengths)

- Compatible with a wide variety of yarn types and sizes

Broad Weaving

- Electronic dobby loom

- Ideal for flat or multi-layer woven fabric that requires laser cutting or post processing

- Maximum width of 20 inches

- Digital equipment allows for quick prototype iterations

- Compatible with a wide variety of yarn types and sizes