Engineered medical textiles are replacing metal and bringing great benefits to today’s robotic surgery platforms. Our textile engineers are here to collaborate and bring value to your robotic surgery projects and innovations.

![]()

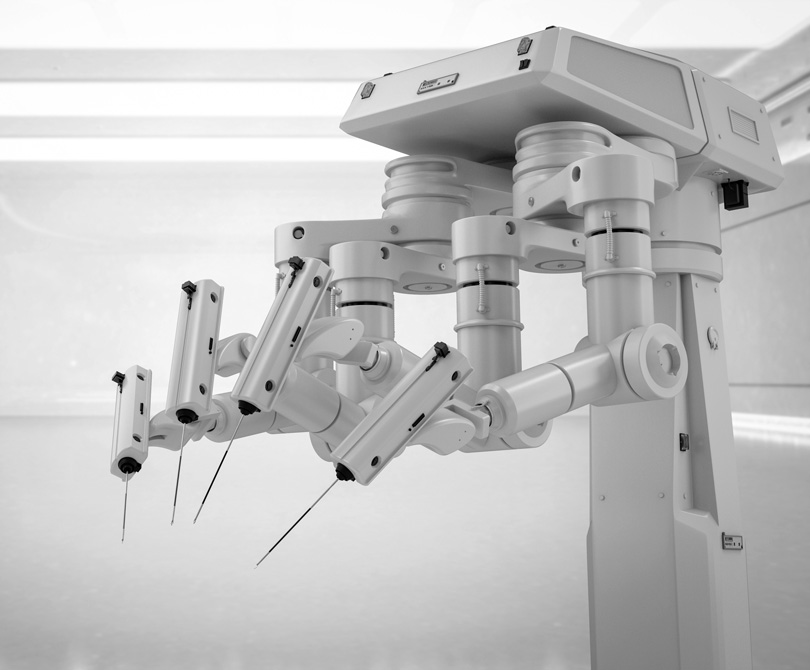

Biomedical Textiles for Robotic Surgery Platforms

Engineered medical textiles are replacing metal and bringing great benefits to today’s robotic surgery platforms. Our textile engineers are here to collaborate and bring value to your robotic surgery projects and innovations.

![]()

With a deep history of innovation in medical textiles, we are leading the way in the incorporation of precision engineered medical textiles for robotic surgery applications. Textiles are a viable and advantageous alternative to traditional metal in robotic devices, thanks in large part to their ability to be thinner, lower profile, cost-effective, and to support better articulation. Incorporation of textiles into surgical robotics systems such as robotic arms, actuators, robotic tendons, and stapling applications enables greater flexibility and smoother movements. For a wide range of surgical applications requiring gripping, cutting or suturing, textiles can give the hand on a robotic device more degrees of freedom and improved orientation.

Important to note, and contrary to some misconceptions, transitioning from metal to textile components in robotic devices does not mean sacrificing strength – in fact, in some cases textiles using modern high-performance fibers can be even stronger than metals, while also having the flexibility to conform to twists, bends and grooves in a device.

Benefits of using textiles in robotic surgery application include:

- Smoother glide, lower coefficient of friction

- Flexible turns

- Better grip

- Smaller, thinner, and stronger than traditional metal

- Multiple material options

- Highly configurable (loops, splices, end terminations, etc.)

- More natural feel for the surgeon

- High stability/inert materials

We work closely with our customers to custom engineer the best solutions possible – whether for specialized robotic solutions for endoscopy, urology, gastrointestinal, or simply general surgery. We aim to strike the right balance of size and strength of braiding parameters and provide extensive mechanical testing – including, but not limited to tensile strength, elongation, and dimensional measurements. Our customers enjoy that textiles have much more compliant properties than metals in terms of torque, flexibility and strength – giving them maximum opportunity for innovation.

Our braids can bear significant weight, and the cylindrical shape makes them well-suited to maintain properties while conforming to twists and turns, whether it be winding through a cannula or transcatheter delivery system. We can customize the characteristics of different zones of a single braid – for example, enabling a high degree of flexibility at the distal end of a braid while being stable in the middle for maximum load bearing.

Our highly skilled hand fabrication capabilities can even create different splices, loops and end terminations that can be used with other braids or terminations within a robotic device.

Learn more about our braiding solutions and products.

With a deep history of innovation in medical textiles, we are leading the way in the incorporation of precision engineered medical textiles for robotic surgery applications. Textiles are a viable and advantageous alternative to traditional metal in robotic devices, thanks in large part to their ability to be thinner, lower profile, cost-effective, and to support better articulation. Incorporation of textiles into surgical robotics systems such as robotic arms, actuators, robotic tendons, and stapling applications enables greater flexibility and smoother movements. For a wide range of surgical applications requiring gripping, cutting or suturing, textiles can give the hand on a robotic device more degrees of freedom and improved orientation.

Important to note, and contrary to some misconceptions, transitioning from metal to textile components in robotic devices does not mean sacrificing strength – in fact, in some cases textiles using modern high-performance fibers can be even stronger than metals, while also having the flexibility to conform to twists, bends and grooves in a device.

Benefits of using textiles in robotic surgery application include:

- Smoother glide, lower coefficient of friction

- Flexible turns

- Better grip

- Smaller, thinner, and stronger than traditional metal

- Multiple material options

- Highly configurable (loops, splices, end terminations, etc.)

- More natural feel for the surgeon

- High stability/inert materials

We work closely with our customers to custom engineer the best solutions possible – whether for specialized robotic solutions for endoscopy, urology, gastrointestinal, or simply general surgery. We aim to strike the right balance of size and strength of braiding parameters and provide extensive mechanical testing – including, but not limited to tensile strength, elongation, and dimensional measurements. Our customers enjoy that textiles have much more compliant properties than metals in terms of torque, flexibility and strength – giving them maximum opportunity for innovation.

Our braids can bear significant weight, and the cylindrical shape makes them well-suited to maintain properties while conforming to twists and turns, whether it be winding through a cannula or transcatheter delivery system. We can customize the characteristics of different zones of a single braid – for example, enabling a high degree of flexibility at the distal end of a braid while being stable in the middle for maximum load bearing.

Our highly skilled hand fabrication capabilities can even create different splices, loops and end terminations that can be used with other braids or terminations within a robotic device.

Learn more about our braiding solutions and products.