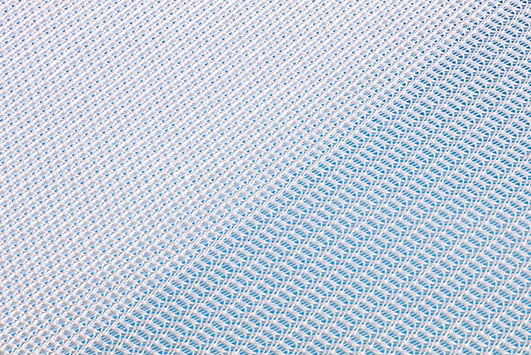

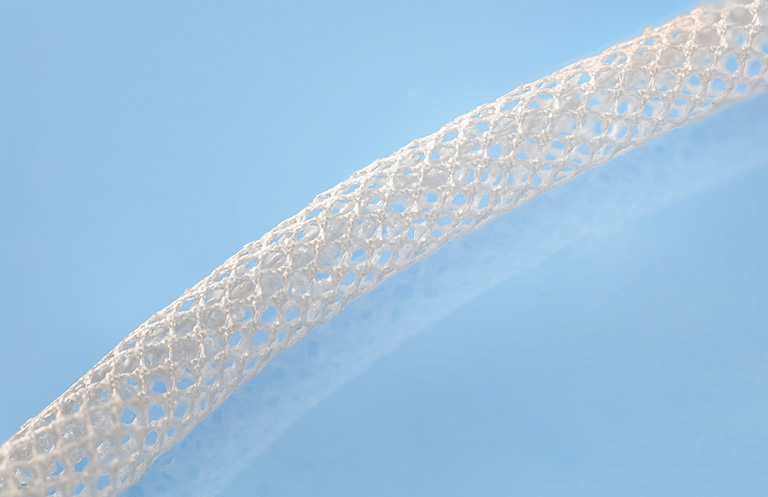

Knitting

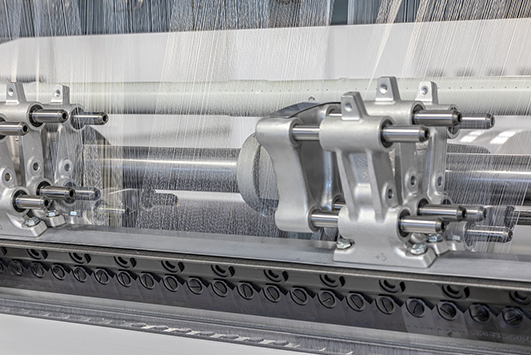

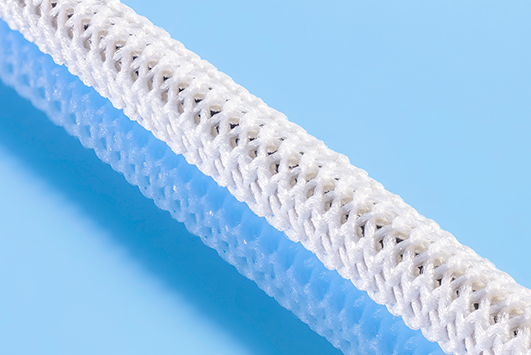

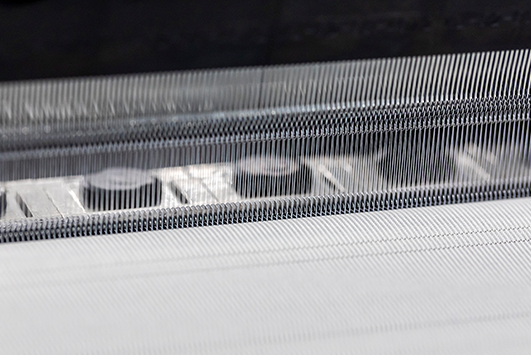

By listening to feedback from the market, Cortland Biomedical has acquired and installed the latest in warp knitting technology and is prepared to design the next generation of knitted biomedical textiles.

![]()

Knitting

By listening to feedback from the market, Cortland Biomedical has acquired and installed the latest in warp knitting technology and is prepared to design the next generation of knitted biomedical textiles.

![]()

Biomedical Textile Knitting Products and Technology

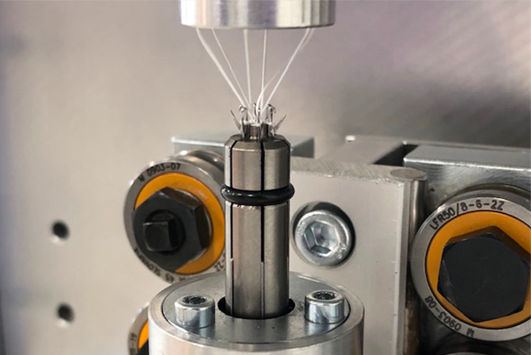

We offer the latest in warp knitting technology – including Tricot, Double Needle Bar, and Circular Warp Knitting – to enable the next generation of knitted biomedical textiles.

Biomedical Textile Knitting Products and Technology

We offer the latest in warp knitting technology – including Tricot, Double Needle Bar, and Circular Warp Knitting – to enable the next generation of knitted biomedical textiles.